- About US

- LPG Industry

LPG Industry

- LPG R&D

- Related Link

Related Link

LPG R&D

LPG R&D LPG Vehicles Technology

LPG R&D LPG Vehicles Technology

LPG R&D

LPG Vehicles Technology

R&D for LPG Vehicles

Korea retains the world's finest LPG vehicle technology as a result of commercializing third-generation Liquid Petroleum injection(LPi) engine, introduced for the first time in the world in 2004. Since 2011, the fourth-generation Liquid Petroleum Direct injection(LPDi) engine has been developed.

LPG engines are divided in the following manner, according to the process of change in the fuel supply and air-fuel ratio control systems, whereas the LPG vehicles currently available in Korea are equipped with the LPi system.

What is LPi engine system?

The third-generation LPi (Liquid Petroleum Injection) engine is a system that sequentially injects LPG, which is delivered by pumps installed inside the LPG tank to the fuel supply line, into each cylinder, using an injector controlled by the electronic control unit (ECU). The LPi system not only fundamentally resolves the jumpstarting problem in winter that is prevalent in the previous mixer type, but also improves power and fuel mileage to deliver comparable performance to gasoline-powered cars.

Development of LPDi vehicles

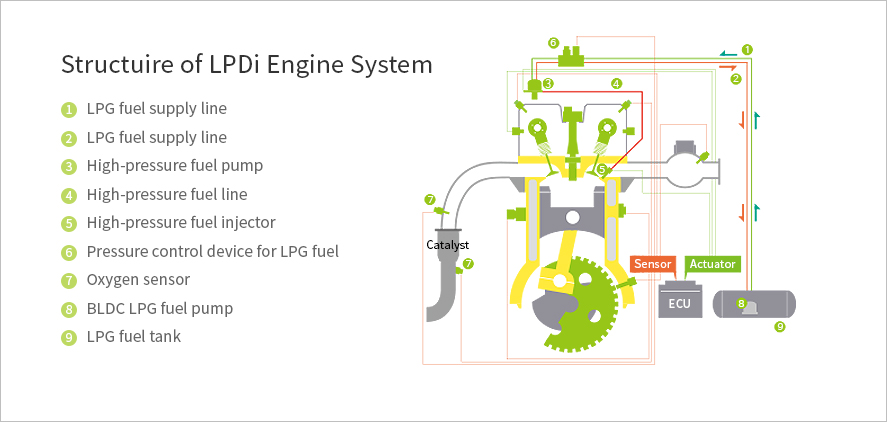

What is LPDi engine system?

The fourth-generation Liquid Petroleum Direct injectionj(LPDi) engine is a next-generation LPG engine system that directly sprays and combusts LPG in liquid state inside the main combustion chamber. Its adaptation of the principle of Gasoline Direct injection (GDi) to LPG has improved both the power and efficiency.

Features of the LPDi engine

The LPDi engine significantly reduces harmful substances such as hydrocarbons (THC) and nitrogen oxides (NOx) compared to gasoline, while maintaining the power level equivalent to that of gasoline to satisfy both the eco-friendly nature and high performance. It satisfies the standards for the EU’s Euro 6 and North America's strictest emissions regulations, SULEV. In addition, the emissions of harmful nano-particles, carcinogenic polycyclic aromatic hydrocarbon (PAH), and volatile organic compounds (VOC) that cause photochemical smog, are much lower than those of comparable GDi engines.

Development of LPDi one-ton truck

Since 2016, the Eco-Friendly Vehicle Development Project Team has been developing the eco-friendly fuel injection and post-treatment system for 1-ton entry-level LPDi commercial vehicles. The vehicles will be commercialized at the end of 2023. The developed LPDi trucks are regarded as an eco-friendly alternative in freight transportation considering their eco-friendliness and outstanding performance better than similar-level diesel trucks.

Greenhouse Gas Reduction Effect of the Next Generation one-ton LPG Truck

| Category |

|---|

| Engine out / torque (PS/kgm) |

| CO2 emissions (g/km) |

| Current diesel truck | Next-gen. LPDi truck |

|---|---|

| 133 / 30.0 | 159 / 30.0 |

| 201 ~ 207 | 185 |

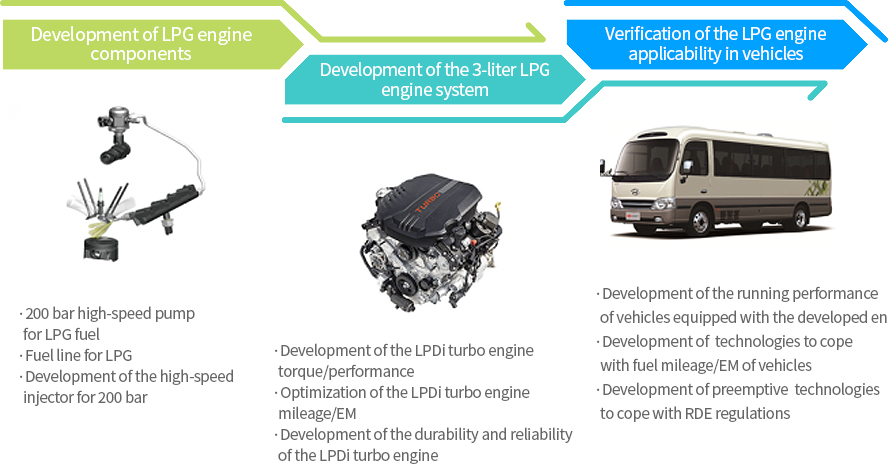

Development of mid-sized and large-sized LPDi engines

The 3-liter LPG direct injection engine parts and system were developed through the Industrial Technology Innovation Project implemented from 2017 to 2021. Mid/large-sized LPDi automobiles emit fewer exhaust gases, showing the identical performance to that of other diesel vehicles. Furthermore, they have outstanding cost competitiveness since they don’t require a post-treatment system such as SCR. 3-liter mid/large-sized LPDi engines are expected to play a major role in improving urban air quality since they can be used for mini buses, mid/large-sized trucks (2.5 to 5 tons), and construction machinery which greatly contribute to air pollution..

Composition of the Technical Development for the Mid-sized and Large-sized LPDi

KOR

KOR